Column No. 23

ALONG THE RUBY ROAD

The Eagle-Picher Lead Company Takes Over the Montana Mine

Bob Ring, Al Ring, Tallia Pfrimmer Cahoon

After the Goldfield Consolidated Mines Company shut down mining operations in

1918, Ruby’s Montana mine remained dormant for eight years.

In the fall of 1926, the Eagle-Picher Lead Company of Joplin, Missouri took out

an option to buy the Montana mine from merchandiser Louis Zeckendorf. The

Company began drilling immediately to examine the production potential of the

mine. Eagle-Picher concluded that they had a potentially profitable venture and

wrapped up the deal on April 1, 1927.

So, after almost 40 years, Louis Zeckendorf finally sold the Montana mine. A new

Eagle-Picher era began.

In 1927, the Eagle-Picher Lead Company was one of the largest white lead and

zinc companies in the United States. Its assets exceeded $45,000,000, with ore

refineries in Kansas and Oklahoma as well as Missouri.

The business leaders of Arizona’s Santa Cruz County must have been overjoyed to

have a company the size of Eagle-Picher begin operations in their county.

F. H. Lerchen, western representative of Eagle-Picher, announced the purchase.

He said that the Company planned to sink the shaft to a depth of four or five

hundred feet from its present depth of 250 feet. At the time of the

announcement, thirty-five men worked at the Montana mine.

The Eagle-Picher Company formed a subsidiary, the Montana Mines Operations

Company, to develop and operate the Montana mine. The Company named as General

Manager, Frank Lerchen, who did the “leg work” evaluating the mine’s prospects.

Eagle-Picher hired mining engineer Walter S. Pfrimmer (the father of columnist

Tallia Pfrimmer Cahoon) to update and enlarge the Montana’s mill and mining

operation.

Drilling continued aggressively to deepen the main shaft and to expose the

complex lead-zinc sulfide ore. The Company started constructing a new $100,000

combined gravity and flotation mill, driven by water, and capable of handling

250 tons of ore per day.

By December 1927, the workforce reached 100 men.

In parallel with this “development period,” Eagle-Picher hired the American

Appraisal Company to estimate the value of the mine, buildings, and equipment.

The Appraisal Company’s report listed 13 existing mining buildings, including a

crusher house, concentrating mill, powerhouse, hoist house, and machine shop.

The report also identified 22 existing camp buildings, including a hospital,

school, general store, boarding house, and 14 dwellings. (The Goldfield

Consolidated Mining Company gave the Eagle-Picher Lead Company a good start on

buildings, having built, a decade earlier, many of the structures that the

appraisal report identified.)

The American Appraisal Company estimated the May 1928 value of the Montana mine

and mining camp at $1.027 million.

Prospects looked good and spirits were high. On April 15, 1928, the Nogales

Chamber of Commerce sponsored a motorcade to visit the Montana mine “so that

Nogales business men may get better acquainted with just what’s doing out that

way, and so they will learn the importance of seeing to it that the Nogales-Ruby

road is quickly repaired in order to bring business from the camp to Nogales.”

This was the same mountainous road that the Goldfield Consolidated Mining

Company used a decade earlier to transport ore concentrates to the railroad at

Plomo Station.

Eagle-Picher completed the new mill and began production operations in May 1928.

The workforce now numbered 150 men. By December 1928 the main shaft was down to

400 feet, with working levels at 100, 200, 300, and 400 feet. The workforce held

at 150 men.

Unfortunately, also, by December 1928, the influenza plague, that devastated the

entire United States, reached Ruby with unusual severity. Of the roughly 400

people living in Ruby, about 125 came “down with the influenza.” Ruby residents

turned a large wooden shed into an improvised hospital. So many workers were

sick, that both the mine and mill shut down for a few days. Thankfully, there

were no deaths, and after some very uncomfortable days and nights, the sick men

recovered and resumed work.

Even with planned improvements, the Nogales-Ruby road was not the road that the

Montana Mines Operations Company wanted to use to transport ore concentrates to

the railroad. They were apparently wary of using the same difficult mountainous

road that had been such a problem for the Goldfield Consolidated Mining Company

a decade earlier. Instead, the Montana Mines Operations Company chose the only

other available route. Eagle-Picher shipped all ore concentrates north from the

mine to Arivaca and then east to Amado (total one way distance of 34 miles).

M. C. Hubbell secured the hauling contract, bringing a fleet of huge

twelve-cylinder Coleman trucks from Denver. At the time, they were the heaviest

trucks seen in Arizona. Each truck pulled a trailer that could carry 12 tons of

ore concentrates. The Coleman trucks made 16-hour round trips from the Montana

mine to Amado and return.

The first operations of the new mill lasted from May 1928 to early that summer,

when the water stored behind the dams ran out. The summer rains provided enough

water to restart the mill operation. This time the mill ran until January 1929,

when the water ran out again. (Note: Four dams impounded water; total capacity

was 40,000,000 gallons. During years of normal rainfall, this was sufficient to

keep the mill running. But the rains often didn’t come on schedule.)

During the shutdown for lack of water, Eagle-Picher made improvements to the ore

concentrating process. The Company also kept digging in the main shaft, reaching

a depth of 700 feet by July 1929.

Production operations resumed in the summer of 1929, after the August rains.

Starting in December 1929, mining operations ran at capacity with an increased

workforce of 250 men.

It seemed that the only problem was the lack of a dependable water supply.

(Sources: Nogales International; Nogales Herald; Tucson Citizen; Douglas Knerr,

Eagle-Picher Industries, 1992; D. E. Andrus, “Milling Methods and Costs at the

Montana Mine Concentrator of the Eagle-Picher Lead Co., Ruby, Arizona,” U. S.

Bureau of Mines Circular 6497, September 1931; “Appraisal Report,” Eagle-Picher

Lead Company, Montana Mine, The American Appraisal Company, March 12, 1928)

|

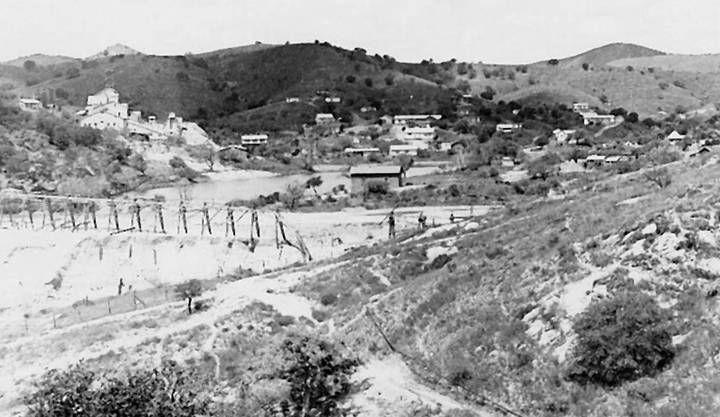

1928 Mill

In 1928, the Eagle-Picher Lead Company began significant mining of lead

and zinc at the Montana mine. The photo shows the newly completed mill.

(Mr. and Mrs. Hugo S. Miller private collection) |

|

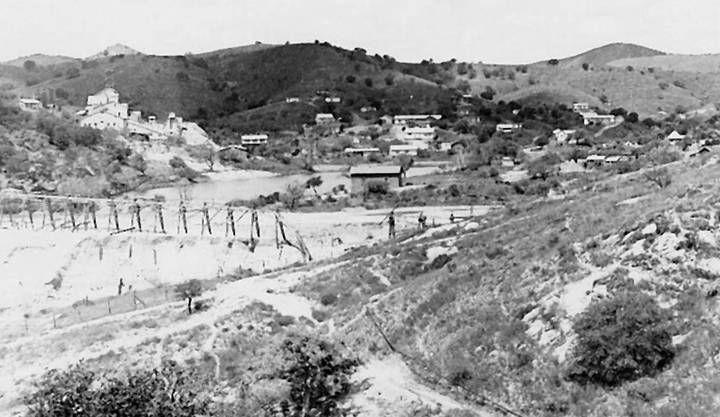

Trestle to Tailings Dump

A trestle carries tailings (ore refuse) pumped from the ore-processing

mill to the upper tailings dam. The Ruby mining camp, with many wooden

buildings, can be seen in the background. Circa late 1920s (Tallia

Pfrimmer Cahoon private collection) |

Next time: More Water, but the Great Depression Hits

Ruby

Back to List of Columns